New students starting in September: You can find out more about Induction Days and other useful information in our Start of Year Guide.

WHY CHOOSE THIS COURSE?

This apprenticeship standard equips apprentices with the skills to maintain and optimise complex automated equipment across industries such as aerospace, automotive, mining, manufacturing, and pharmaceuticals. Apprentices will gain expertise in mechanical, electrical, electronic, and control systems, ensuring plant and equipment meet high standards of safety, quality, and efficiency. With hands-on experience in installation, testing, fault-finding, and planned maintenance, apprentices will be prepared to tackle diverse challenges in various environments, from factories to workshops. Join us to develop your technical skills and achieve professional recognition in a field that is integral to modern industry.

Apply for this course

Start date: 03/11/2025

TOP COURSE HIGHLIGHTS

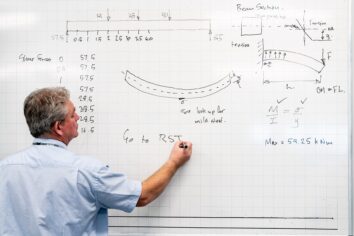

Industry-standard facilities

Highly experienced tutors

Develop skills in line with industry needs

Learn from sector experts

Gain invaluable insights and hands-on experience from industry expert tutors who bring real-world knowledge and expertise to the classroom. Their guidance will help you develop the skills and confidence needed to excel in your chosen field.

Develop work-related skills

Enhance your practical abilities and gain hands-on experience that directly translates to the workplace. This apprenticeship course focuses on real-world applications, ensuring you are well-prepared to meet the demands of your chosen career.

Enjoy professional surroundings

Immerse yourself in a dynamic and supportive environment that mirrors the professional world. This apprenticeship course provides access to state-of-the-art facilities and resources, helping you to thrive and feel confident in your career journey.

WHAT WILL I LEARN?

Knowledge This apprenticeship equips apprentices with comprehensive knowledge in various disciplines, including mechanical, electrical, electronic, and control systems. They will learn about the principles of fluid power, including hydraulics and pneumatics, and how these systems are used in automated equipment. The programme covers safety regulations and standards, ensuring apprentices understand the importance of maintaining a safe working environment. Additionally, apprentices will study the integration of automated equipment, learning how different systems and components work together to create efficient and reliable machinery. This includes understanding complex systems and interfaces, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and robotics, which are essential for modern manufacturing and engineering processes.

Skills This apprenticeship equips learners with practical skills in installation, testing, fault-finding, and planned maintenance of automated equipment. Apprentices will develop the ability to rectify issues, perform modifications, and carry out ongoing maintenance activities. They will also learn to prepare for maintenance tasks, communicate effectively with stakeholders, and adhere to safe engineering practices. Examples of tasks include installing and testing new machinery, diagnosing and fixing faults in automated systems, performing routine maintenance to prevent breakdowns, and updating technical documentation.

Behaviours Apprentices are expected to demonstrate a proactive approach to safety, effective communication, teamwork, adaptability, and a commitment to continuous improvement and professional development.

Typical Duties that an Apprentice will carry out in the workplace:

- Installation: Setting up new automated machinery and equipment, ensuring they are correctly integrated into existing systems.

- Fault-Finding: Diagnosing and troubleshooting issues in mechanical, electrical, electronic, and control systems to identify and rectify faults.

- Planned Maintenance: Performing routine maintenance tasks to prevent equipment breakdowns and ensure optimal performance.

WHERE WILL IT TAKE ME?

Completing the Mechatronics Maintenance Technician Apprenticeship opens doors to a variety of career opportunities in the advanced manufacturing and engineering sectors. Apprentices can progress to roles such as Maintenance Engineer, Automation Engineer, or Systems Technician. With experience, there are further opportunities to advance into supervisory or managerial positions, or to specialise in areas like robotics, control systems, or project management.

ASSESSMENT ARRANGEMENTS

The End-Point Assessment (EPA) is a crucial component of apprenticeship standards, designed to evaluate an apprentice’s knowledge, skills, and behaviours (KSBs) acquired during their training. The EPA typically includes a combination of practical assessments, professional discussions, and portfolio reviews, ensuring apprentices are fully prepared for their chosen career. This assessment is carried out independently by an End-Point Assessment Organisation (EPAO), ensuring impartiality and fairness. Employers play a key role in confirming readiness for the EPA, supporting apprentices throughout the process to achieve successful outcomes.

EPA (End Point Assessment) methods

- Practical Observation with Questions

- Professional Discussion (Interview) underpinned by a Portfolio of Evidence

ENTRY REQUIREMENTS

Grade 4 GCSE (C) in English and Maths plus one other relevant subject.

Meet the staff, tour the campus and find out about life as a student at one of the best colleges in the country.